stainless steel pricelist

Home

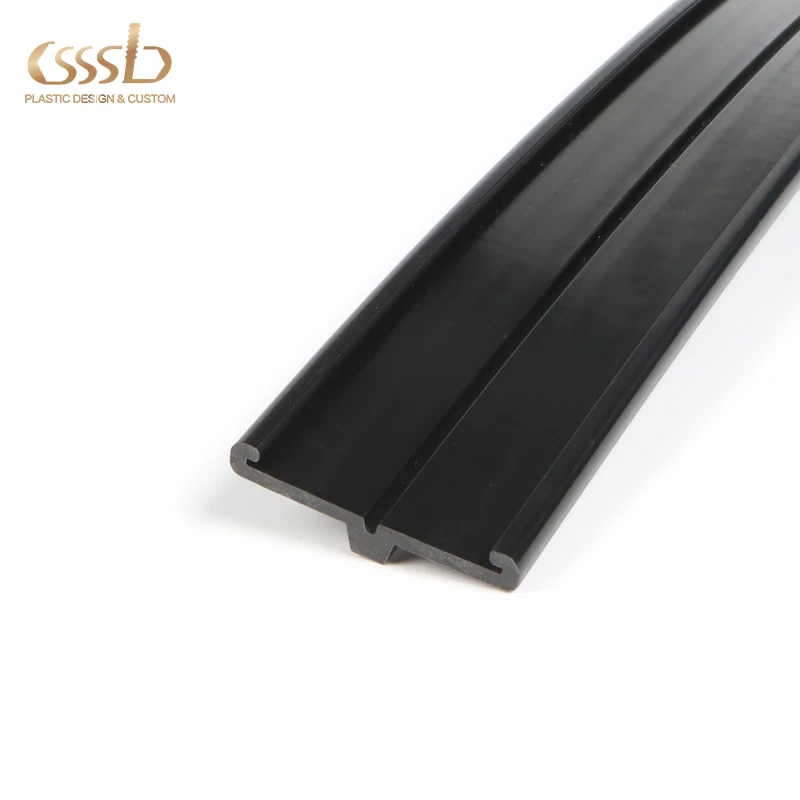

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time

These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time These seals can withstand harsh conditions, resist degradation from chemicals and weathering, and maintain their effectiveness over time